All Posts, Helpful Info, Printing Equipment

Superior Black Adhesive: Revolutionising DTF Printing

Superior Black Adhesive is revolutionising the Direct to Film (DTF) printing industry.

This powerful next generation adhesive, with its unique properties, is setting new standards in print quality and durability.

The use of Superior Black Adhesive when printing your DTF transfers has seen a surge due to its ability to enhance design integrity when used on on darker fabrics.

As DTF Technology is rapidly advances, it is easy to get left behind, that is why at DTF Transfers Australia we are continually testing new products, and we don’t just take the manufactures word on it we fully test out these advancements before we add them to our production process.

The New Generation of Superior Black Adhesive is just one of these products, let us cover why it is great to use for your DTF Transfers.

Table Of Contents:

- The Power of DTF Printing and Its Rising Popularity

- The Integral Role of Quality Adhesive in DTF Printing

- The Evolution of the Black Adhesive

- Optimal Curing of the Superior Black Adhesive

- Optimal Storage for Superior Performance

- Latex Free – A Safer Alternative

- In Conclusion

The Power of DTF Printing and Its Rising Popularity

DTF transfer printing, is a method that has revolutionised the garment industry, and is gaining rapid traction. The technique allows for vibrant prints that are hard wearing and look good.

This technology has paves the way for limitless creative potential by enabling intricate detailing in designs with the ability to be printed onto most fabrics, that in the past would have be challenging with some traditional methods. Many businesses are now leveraging this innovative solution to deliver high-quality products.

Vibrant Prints: Setting New Standards

One notable advantage offered by DTF printing lies in its capacity to generate exceptionally vibrant prints. This process yields rich colours that accurately capture every detail, resulting in unparalleled quality full colour print.

Innovations such as recent advancements in ink, film and adhesive technologies have significantly contributed to enhancing colour saturation without compromising on durability or washability factors associated with these printed materials, if anything it has been improved.

Durable Prints: Designed To Endure

Besides delivering visually appealing results, DTF printing offers superior longevity compared to alternative techniques like screen-printing or heat transfer vinyl (HTV). When quality materials are used to create the Transfers they withstand repeated washing cycles without fading away over time. This is a crucial factor when creating items meant for regular use such as t-shirts, hoodies, and tote bags, where resilience matters most.

A World Of Limitless Creative Potential

Creativity thrives best when it is not constrained by boundaries. Artists and designers alike appreciate the virtually boundless scope of expression afforded through using DTF Transfers. Whether it involves detailed illustrations, multicoloured gradients, photographic images, text-based designs, or whatever else one can imagine, the possibilities are truly endless. DTF is thus a highly versatile method, enabling it to be applied not only to nearly any type of fabric but also onto hard surfaces such as wood, metal, plastic and glass – making it suitable for an array of industries beyond just fashion.

Rising Popularity Amongst Businesses and Hobbyists Alike

We’ve witnessed increasing interest both amongst business owners and hobbyists in recent years, largely due to the advantages outlined, many small t shirt labels that are run from home are moving to this exciting decoration method to create their T Shirts and Apparel that they sell, as it lets them print their designs as they sell them allowing the small business owner to operate with less stock on hand and decrease their overheads.

DTF printing is revolutionising the garment industry with its ability to produce vibrant, durable prints. With recent advancements in ink, film and adhesive technologies and limitless creative potential, it’s no wonder this innovative solution is gaining popularity among businesses and hobbyists alike.

The Integral Role of Quality Adhesive in DTF Printing

With Direct to Film (DTF) printing, quality adhesives are paramount. They form the crucial link between your chosen design and the fabric, ensuring a seamless bond that results in prints with longevity and a quality look and feel.

With rapid advancements shaping this industry, we have seen adhesive formulations undergo significant transformations. Among these is DTF Transfers Australia’s next-generation Black Adhesive, an innovation that has exceptional bonding strength and durability, while giving the transfer a softer hand feel, with the added bonus of having a blocking effect.

Demystifying the Functionality of the Superior Black Adhesive

An adhesive serves as a unifier within the process – bridging vibrant designs on one side with garment materials on another. Its role? To bind these elements into one cohesive entity while maintaining print integrity.

A key factor determining how effectively an adhesive performs lies hidden within its formulation. For instance, TPU (Thermoplastic Polyurethane) – is known for their quick curing time and robust bond formation capabilities – and it stand out due to the unique properties it has and it’s ease of use, but not all of these adhesives are created the same. Some formulas are far better than others, And after testing we have found that the new Superior Black Adhesive, is the best we have tried to date.

The Evolution of the Black Adhesive

From its initial use with a course black adhesive, that had a thick and plastic feel the evolution has been significantly. The progression is particularly evident in its application on challenging materials such as polyester with poor sublimation properties. The New Generation of Superior Black Adhesive with its unique composition allows it to bond effectively with a soft hand feel and it also has good blocking proprieties.

Why Choose Black?

In Direct-to-Film (DTF) printing, choosing the right type of adhesive can have profound implications for your design’s longevity and quality. There are several options available today; however, none quite compare to next-generation black adhesives that exhibit superior performance on darker fabrics without compromising design integrity.

This enhanced performance owes much to the pre-coloured nature which provides an opaque layer between the print and the fabric – ensuring designs retain their vibrancy regardless of base material colouration.

When to Use Black Adhesive?

The Superior Black Adhesive is not perfect for every job, but we find it is most helpfull when you are printing onto Black or dark garments, difficult to print materials, or when printing onto Polyester and you are having a sublimation problem, the use of our Black adhesive can help you signifiantly in your fitting onto these products.

Optimal Curing of the Superior Black Adhesive

Our recommendation for our adhesive is 110ºC for 135 seconds, it is important to do your own testing with your equipment. Different curing methods will require different drying time. It is very important to do your own testing and get your curing time and temperature correct for the process and equipment you are using, for more information on Curing DTF Transfers you may find Our article on it helpful.

Optimal Storage for Superior Performance

The efficacy of black adhesive is not just about its application. The storage conditions also play a crucial role in determining the performance quality and longevity of this product.

A Comprehensive StorageGuide

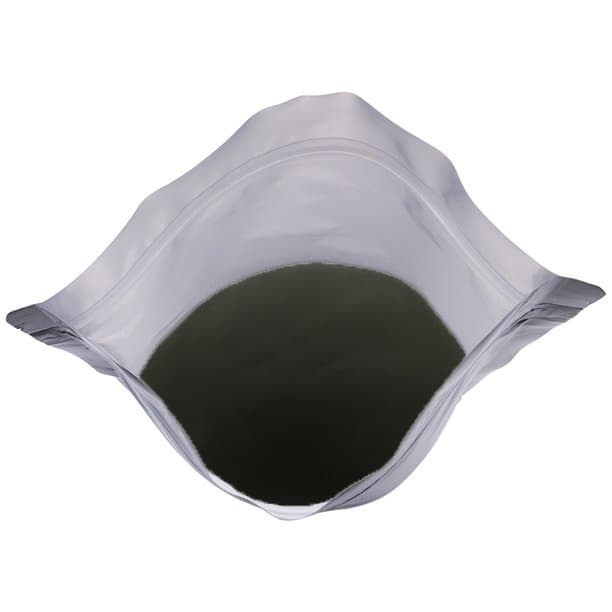

For DTF adhesives specifically used in the creation of DTF transfer, such as ours at DTF Transfers Australia, it is suggested that these should be stored at room temperature away from direct sunlight or heat sources to maintain shelf life and consistent bonding time. It is also important to store them away from humidity, that is why we supply them in reselable bags with a one way valuve to remore the air from the bag after you use the adhesive.

Maintaining Ideal Conditions for Optimum Results

When it comes to achieving optimum results with our black adhesive, maintaining ideal conditions is crucial. Here are some key factors to consider:

- Temperature: It is recommended to store the adhesive at room temperature to ensure its stability and effectiveness. Extreme temperatures can affect the adhesive’s performance and shelf life.

- Light Exposure: Direct sunlight can degrade the quality of the adhesive. Hence, it is essential to keep the adhesive in a dark or opaque container to avoid any exposure to sunlight.

- Humidity: Some adhesive formulations are sensitive to humidity levels. Storing them in a dry atmosphere is suggested to avert any moisture uptake that may influence their operation.

- Sealed Containers: To maintain the adhesive’s freshness and prevent it from degrading over time, always store it in a tightly sealed container. This will also help to prevent any contamination.

By following these guidelines, you can ensure that your black adhesive remains in optimal condition, delivering superior results in your DTF printing.

Storing black adhesive correctly is paramount for its efficacy and longevity. Keep it at room temperature, away from sunlight, in a dry environment and sealed container. This ensures top performance in DTF printing.

Latex Free – A Safer Alternative

Safety and quality are paramount with garment printing. In light of the potential dangers posed by natural rubber latex, it is essential to switch to a safer alternative such as a latex-free adhesive when it comes to DTF printing.

The choice for a latex-free adhesive provided by DTF Transfers Australia not only guarantees high-quality prints but also ensures everyone’s safety who comes into contact with these products.

Risks Associated with Latex-Based Adhesives

Despite their prevalent use in various industries due to their strong bonding properties, latex-based adhesives pose several health risks. Extended exposure can lead to allergic reactions like contact dermatitis or even life-threatening conditions like anaphylaxis in severe cases.

Besides this, they often contain volatile organic compounds (VOCs), which negatively impact indoor air quality leading to headaches or dizziness upon prolonged exposure.

![]()

Mitigating Health Risks Through Latex-Free Alternatives

By shift from using latex-based products significantly reduces the risk of allergy development among those frequently handling them. This change eliminates potential concerns about allergens present in printed garments amongst consumers too.

Beyond being hypoallergenic, DTF Transfers Australia’s Superior Black Adhesive formulations manufactured without any trace of latex deliver superior performance characteristics – providing excellent adherence strength while maintaining flexibility and durability on your printed transfers.

Maintaining Quality Standards Without Compromising Safety

The proprietary resin technology offered by DTF Transfer Australia, free from any traces, ensures robust bonds between fabric and design whilst retaining vibrant colours and sharp details.

When using DTF Adhesive and DTF Transfers it is paramount to work in a well ventilated area, as there are fumes that will be created during the production process, and any health problems can easily be alleviated by working in a well ventilated work area. Avoid contact with your eyes, mouth and nose, do not inhale the advesive, the adhesive is not for human consumption.

DTF Transfers Australia’s latex-free adhesives are not just a safer alternative, but they also deliver superior print quality and durability. By ditching the health risks associated with latex-based products, these advanced adhesive solutions ensure vibrant prints that last, without compromising safety or convenience.

In Conclusion

DTF printing has made a significant impact in the garment industry, with its ability to produce vibrant and durable prints.

The adhesive plays a critical role in this process, ensuring that designs adhere well to the fabric for longevity and quality of prints.

The Superior Black Adhesive has evolved as an ideal solution for challenging materials like polyester due to its excellent blocking properties.

Proper storage conditions are crucial for maintaining the effectiveness of black adhesive – optimal temperature, humidity range, avoiding direct sunlight, and keeping it at room temperature and avoiding high humidity are key to getting good shelf life and continuous print quality.

If you’re seeking high-quality results from your DTF printing process or looking into safer alternatives such as latex-free adhesives…

When you pair our Adhesives with a Quality DTF Transfer film you will get outstanding results.

Discover Superior Black Adhesive at DTF Transfers Australia. Revolutionise your custom printed T-shirt transfers today by integrating our next-generation black adhesive into your production line. You’ll experience enhanced print quality and durability that will truly set your creations apart.