Direct To Film, Helpful Info

Polyester Printing with Low Temp Hot Peel DTF Transfers

Remember when the only way to print on polyester easily was through dye sublimation? Times have changed with the addition of Low Temp Hot Peel DTF Transfers. DTF Transfers Australia is revolutionising how we think about fabric printing, especially for screen printers and hobbyists craving simplicity in T-shirt transfers designer for polyester. Gone are the days of complex processes and limited possibilities.

The textile world’s latest buzz isn’t just a fleeting trend; it’s a substantial shift towards efficiency and versatility. Imagine transferring vibrant designs onto your garments without worrying about material restrictions or the colour bleeding from the T Shirt into the print. That’s what Low Temp Hot Peel DTF Transfers brings to the table.

Why does this matter now more than ever? Our craving for unique clothing is soaring, and the fashion world’s sprint towards quicker turnaround times amplifies why this innovation matters immensely now. With Custom DTF transfers, small print shops can compete with larger outfits by offering high-quality, customisable options that don’t break the bank or require industrial-sized setups.

This method isn’t just another tool in your arsenal—it could very well be THE game-changer you’ve been waiting for. Let’s take a quick trip through why.

Table Of Contents:

- The Evolution of Polyester Printing Technologies

- Welcome DTF Printing: The New Kid on the Block

- The Technical Advantages of Low Temp Hot Peel Transfers

- The Application Process Explained

- Why Home Irons Don’t Make the Cut

- Sizing and Availability of Low Temp Hot Peel Transfers

- Implementing Low Temp Hot Peel DTF Transfers in Your Business

- Innovations in Fabric Printing Technology

- Conclusion

The Evolution of Polyester Printing Technologies

Remember the days when printing on polyester felt like trying to write a love letter with a water gun? Back then, it was a chaotic affair, akin to navigating through a storm without a compass, frequently ending in outcomes that fell short of our hopes. But boy, have we come far from those early attempts.

Dive into the tale of two pivotal heroes in this journey: traditional dye sublimation and its cool younger sibling, DTF (Direct-to-Film) printing. Both have played their parts in revolutionising how we print on polyester, making what seemed impossible yesterday’s possible today.

From Heat To Print: The Rise of Dye Sublimation

Let’s start with dye sublimation. This process is like that reliable friend who’s always got your back. Using the heat press to create the magic, it transforms solid ink into gas without passing through the liquid phase – think dry ice but for ink. It then embeds itself onto polyester fabrics by bonding to the fibers of the material. Simple yet effective.

T-Shirt Printing on Polyester Using Dye Sublimation: A Detailed Look

In the vibrant world of custom apparel, dye sublimation on polyester t-shirts stands out for its quality and durability of the print. This sophisticated process is not just about transferring a design onto fabric; it’s a transformation that requires specialised equipment, knowledge, and materials. Let’s delve into why dye sublimation is the go-to method for polyester t-shirts, highlighting the necessity of specialised printers and inks, and its suitability only for light-coloured fabrics.

The Magic of Dye Sublimation

Dye sublimation is a two-step process that involves printing a design onto a special paper and then using heat to transfer that design into the fabric. Unlike traditional printing methods, dye sublimation turns the solid ink into a gas without passing through a liquid phase (sublimation), which then permeates the polyester fabric and solidifies into the fibres when the heat is removed. This results in a vibrant, sharp image that is as much a part of the fabric as the fabric itself.

Why Specialised Printers and Ink Are Essential

The dye sublimation process requires a printer that’s specifically designed for sublimation printing. These printers are capable of handling the sublimation inks and transfer papers required for the process. Sublimation inks are unique because they can transition from a solid to a gas without becoming a liquid. This characteristic is crucial for the dye to integrate seamlessly with the polyester fibres.

Regular inkjet or laser printers cannot be used for this process, as they are not designed to handle these inks required for sublimation printing. The sepecility ink is paramount to achieving the vivid colours and durability that dye sublimation is known for, while it is liquide during the printing process, once dry on the special paper (yes even the paper is special) it sublimates when heat is applied making the process work as intended.

Suitability for Light-Coloured Polyester T-Shirts

Dye sublimation is particularly suited for light-colored polyester fabrics. The reason behind this is twofold: First, since the dye becomes part of the fabric, the underlying color of the fabric can significantly influence the outcome of the print. Light or white fabrics provide a blank canvas that ensures the colors in the design will show up true to tone and vibrancy.

Second, polyester is the ideal fabric for dye sublimation because of its synthetic nature. Polyester fibers open up under high heat, allowing the gasified ink to enter and then solidify into the fibers as they cool. This process does not work as well on natural fibers like cotton, which do not have the same properties to fully bond with the sublimated dye.

Wrapping up Dye sublimation

Dye sublimation on polyester t-shirts offers durability, quality, and color vibrancy, making it a preferred method for custom apparel and promotional items. However, the success of this printing technique lies in the use of specialised sublimation printers and inks, alongside its application on light-colored polyester fabrics. For businesses and designers looking to create high-quality custom apparel, understanding the nuances of dye sublimation is key to leveraging its full potential.

While we do not offer Dye Sublimation transfers there are business out there that do, and if you are only doing light colour polyester T Shirts and apparel, this might be the perfect option for you.

Remember struggling with polyester prints? Now, dye sublimation and DTF printing have changed the game, making once impossible tasks easy and broadening our creative horizons.

Welcome DTF Printing: The New Kid on the Block

Cue dramatic entrance music because here comes custom DTF printing; sleeker and more versatile than ever before. This innovative tech allows us to digitally print designs onto special films which are then transferred under heat onto pretty much any fabric type – yes even that stubborn poly-cotton blend hanging at the back of your wardrobe.

Understanding Low Temp Hot Peel DTF Transfers

Let’s dive right in, shall we? In the realm of Direct-to-Film (DTF) printing, a flurry of groundbreaking advancements is stirring excitement. But one standout advancement that’s turning heads is the Low Temperature Hot Peel DTF Transfer. Diving into why it’s revolutionising the scene, this innovation is seriously shaking things up (in a good way).

What Makes Them Stand Out?

The clue’s in the name – “Low Temp”. Applying these transfers requires less heat than the usual DTF Transfers, offering a gentle touch to materials once considered too fragile for the scorching embrace of conventional methods. So, this not only makes them gentler on your textiles but also unlocks a whole new realm of potential for fabrics once thought too difficult to print using the high-temperature transfers.

Then there’s the “Hot Peel” part. Picture this: you’ve just pressed your design onto a tee. With traditional transfers, you’d wait an eternity before peeling off the backing film, fingers crossed it all went well. But with hot peel technology? You can peel almost immediately after pressing—no waiting, no guesswork.

And yes we know that the original DTF Transfers could be fitted onto Polyester garments, but there was a little more to this than just fitting the transfer, you needed to experiment with the temperature and settings, check it on the polyester you pland on fitting it to. And then the durability of the transfer if not done correctly could be signifantly reduced.

A Closer Look at Their Benefits

- Fabric Friendliness: Say goodbye to scorched garments and hello to happy customers when their favourite delicates come out looking fresh as daisies.

- Ease of Use: It simplifies life behind the heat press; quick application times mean faster turnaround for orders.

- Versatility: From polyester tees to nylon bags and beyond – if you can think it, chances are low temp hot peel transfers can handle it.

- Cotton Friendly as Well: the Low Temperature Hot Peel Transfers are able to be used on cotton as well, if you have created some transfers for a polyester job and need to do a couple of cotton tee’s as well, no problems these work just as well on cotton as they do on polyester.

Saving Time & Money

We’re always hunting ways to be more efficient without cutting corners, right? That’s where these low temp wonders shine bright like diamonds in rough production schedules—they streamline operations while keeping your products a quality finish.

All things considered; custom low temperature hot peel DTF transfers aren’t just another step forward in printing tech—they’re leapfrogging into new territories altogether. They’ve got folks rethinking what’s possible from their print shops and pushing creative boundaries further than ever before.So why not give them a whirl and see how they revolutionise your prints?

Dive into the future of printing with Low Temp Hot Peel DTF Transfers. They’re kind to fabrics, easy to use, and super versatile – perfect for pushing creative limits without sacrificing quality or efficiency. See how they can transform your prints today.

The Technical Advantages of Low Temp Hot Peel Transfers

Let’s talk why these are a game-changers in the textile printing industry, and top of that list, Low Temp Hot Peel DTF Transfers. These aren’t merely an alternative for your creations; they completely transform our perspective on imprinting patterns onto fabric, making it easier to print Polyester and other difficult materials.

Eliminating Dye Migration

Ever noticed those annoying instances when colours seem to have a mind of their own, wandering off and distorting your print? That’s dye migration or sometimes called colour mirgation – a common headache in sublimated polyester or other synthetic fabrics. But here comes the knight in shining armour: Low Temp Hot Peel Transfers.

This innovative tech, due to it low temperature fitting, keeps colours right where you want them. No more find the red of the T Shirt has decided it prefers being in the white of the print, turning it pink, rather than staying put and the print looking vibrant and chrisp.

You see, high heat is often what gives dye molecules wings, letting them fly into places they shouldn’t. By keeping things cooler, these transfers make sure every colour stays true—no mix-ups, no migrations. Just crisp, clear designs exactly as you envisioned them.

In essence, if you’ve been chasing after perfection in your prints on polyester but felt like something was always amiss – chances are it was dye migration throwing a spanner in the works. With Low Temp Hot Peel Transfers though? Consider that problem history.

A little technical tweak can mean big improvements for your final product – making life easier and the outputs way prettier. So why settle for anything less?

Low Temp Hot Peel DTF Transfers change the game by keeping colours in place, eliminating dye migration. This means sharper designs, more vibrant colours, and longer-lasting prints without the hassle of colour bleed or fade. It’s a simple switch with big benefits for your textiles.

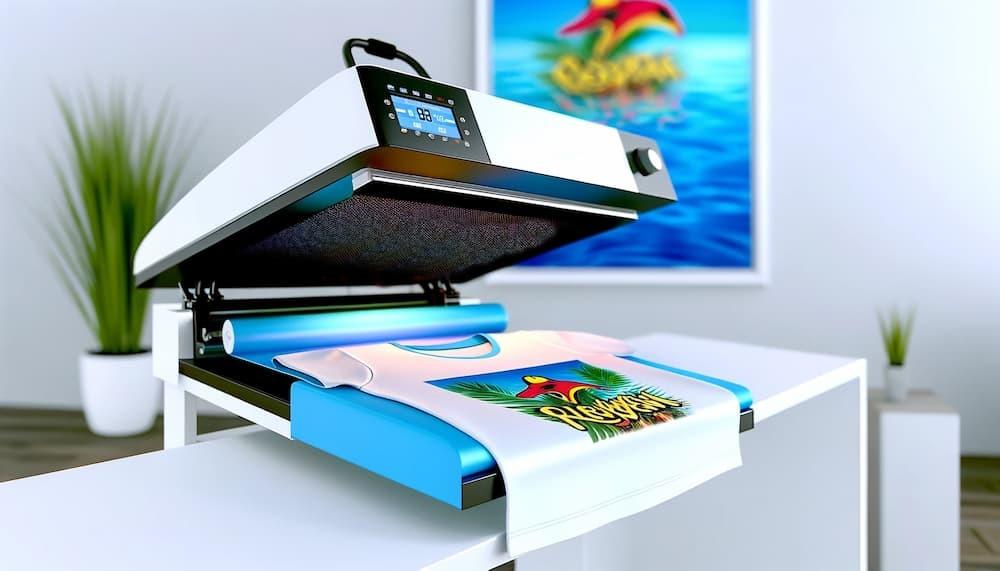

The Application Process Explained

Let’s walk through the journey of applying Low Temperature Hot Peel Transfers to your garments. We’re aiming for those quality results that make people go, “Wow.”

Preparing Your Garment

Picking the right garment is like choosing the perfect canvas for your masterpiece. When it comes to applying heat transfers, remember that not every material is on the same level of suitability.

Applying the Transfer

This step is where magic meets method. Meticulousness and endurance are paramount virtues here.

- Temperature setting: Set your heat press between 110°C – 120°C. Too hot, and you risk scorching; too cool, and it won’t stick properly.

- Cover Up: When printing onto polyester, using a cover piece of material the same as the material that you are fitting the transfer to can help remove heat press marks.

- Press time: Lock down the heat press using firm pressure for about 12-15 seconds. Like baking a cake, timing matters.

- Then peel: The transfers are hot peel so no waiting around you can peel them straightaway.

The Final Press

Last but certainly not least: The final cure – think of it as sealing in all that hard work.

- Re-Press: Using the same temperature and time repress with a cover sheet over the transfer this can be parchment paper or baking paper, both will work well. Open the heat press and remove the cover sheet. Now remove the garment from the press and allow to cool before you package it.

And there you have it, you’ve successfully navigated through applying Low Temp Hot Peel Transfers onto a garment from start to finish. Remember, practice makes perfect and with each attempt, you refine your technique even further. Remember testing and adapting the settings is key, so don’t get discouraged if your first few tries aren’t flawless. Perfection is within reach with persistence and patience hand in hand, together you can create stunning pieces to showcase your talent and style. Let your creativity shine bright, unbounded possibilities await your exploration and discovery.

Get quality prints with Low Temp Hot Peel Transfers by choosing the right fabric, setting the correct heat, pressure and time, then sealing the deal with a final cure. Practice makes perfect for stunning results.

Why Home Irons Don’t Make the Cut

Let’s talk about why grabbing that home iron, sitting pretty on your ironing board, isn’t going to cut it for Low Temp Hot Peel Transfers. Sure, we’ve all been there – thinking a quick press at home might just do the trick. But here’s the scoop: it won’t.

First off, consistency is key. Your typical home iron? It’s like playing temperature roulette. You need precise heat control which most irons can’t offer. And when you’re dealing with Low Temp Hot Peel DTF transfers, precision is not just nice to have; it’s essential.

Then there’s pressure. Ever attempted to wrap your arms around a massive elephant in an embrace? That’s how much pressure you need for these transfers – something no household iron can muster without turning into a gym session.

- Missing consistent temperature control = A poor quality transfer.

- Lack of adequate pressure = The transfer will not adhere properly.

We haven’t even touched on size yet. Picture this: You’ve got a gorgeous design ready to transform your garment but oops… your home iron does not cover even half of it at best. Uneven application alert.

The Alternatives?

Achieving professional results calls for professional tools:

- A dedicated Heat Press:The real MVP here, offering uniform temperature and pressure across larger surfaces than any sad little iron could dream of handling.

- Think a flat heat presses.

- Dedicated DTF Printers & Supplies: To make sure every print comes out vibrant and durable, consider investing in quality custom DTF Transfers for DTF Transfers Australia.

Last bit of advice? Don’t skimp on quality tools if high-quality output is what you’re after.Remember,“Good work ain’t cheap,Cheap work ain’t good.” Sage words by Sailor Jerry that ring true in today’s custom printing world.

Home irons fall short for Low Temp Hot Peel Transfers due to inconsistent temperature, inadequate pressure, and small size. Professional heat presses are a must for delivering high-quality results.

Sizing and Availability of Low Temp Hot Peel Transfers

So, you’re all set to dive into the world of Low Temp Hot Peel Transfers. But hang on a minute. Before we start creating magic with these transfers, let’s talk about what sizes they come in and how you can get your hands on them.

Available Sizes:

- Gone are the days when one size had to fit all. These transfers come in various sizes to suit your project needs perfectly.

- Whether it’s for a small logo or a full-shirt design, there’s something for everyone.

Our Sample Pack – Try Before You Buy Big:

- If commitment scares you, why not dip your toes in first? Our Sample pack is here to save the day. And it is absolutely fee, just fill in the form and we will send one out to you, as well as adding you to our monthly email to keep you up-to-date on what is happening in the world of DTF.

- With a full range of the transfers we offer you can give it a go and see what works best for you.

Embarking on the journey of exploring new printing methods can often seem like navigating through unknown territories. That’s why as sample pack is not just practical; they’re peace of mind packed neatly into an envelope waiting at your doorstep.

Ordering Your Custom Transfers:

- The process couldn’t be simpler. Head over to our website where freedom meets creativity.

- Download our Photoshop templates. Create your transfers in Photoshop, save as a .png with transparent background.

- Select from our range of available sizes. Upload your artwork, checkout, and we will do the rest

- Once you’ve chosen either local pick-up or shipping, wait for your transfers to be ready for collection or delivered. Upon receiving them, follow the supplied instructions to apply them. Remember to conduct some tests since heat presses vary and may require slight adjustments in temperature or time for optimal results.

- Enjoy, this can be a rewarding process, enjoy and have fun.

Incorporating Low Temp Hot Peel DTF Transfers into your projects isn’t just about upgrading print quality—it’s about embracing flexibility and innovation hand-in-hand. Whether it’s scaling up operations or experimenting with creative ideas on different fabrics that were once considered tricky, these transfers have got you covered (literally).

Implementing Low Temp Hot Peel DTF Transfers in Your Business

So, you’ve got a screen printing or small print shop and you’re looking to up your game? Enter the world of Low Temp Hot Peel DTF Transfers. This isn’t merely a fleeting trend; it’s an innovative shift that promises to elevate your production caliber and broaden your options. Explore how you can unlock this potential. Your customers will thank you.

Understanding the Basics

First things first, let’s get our heads around what we’re dealing with here. Low Temp Hot Peel DTF transfers are essentially a method where designs are printed onto special films which then get transferred onto fabric using heat presses – but at lower temperatures than traditional methods. What does this mean for you? Less damage to delicate fabrics and more versatility in what you can offer customers.

Gearing Up

- The Right Equipment: To start, ensure your heat press is capable of consistent low-temperature application. If not, consider an upgrade because precision matters here.

- Sourcing Quality Supplies: High-quality transfer matter too. They’re crucial for vibrant, long-lasting prints that won’t crack or fade after washing.

- Remember DTF Transfers Australia produce your custom transfers using quality film, inks and adhesives.

Educating Your Team

You’ve got the gear; now make sure everyone knows how to use it properly. Training sessions on handling new materials and equipment will save time (and money) down the line by reducing mistakes made from guesswork. By helping your team understand how to fit these new transfers will save you money in the long term, and reduce mistakes.

Promoting New Offerings

All geared up? Brilliant. But don’t keep it under wraps – shout about these new offerings through all channels available: social media platforms, email marketing campaigns even old-school flyers if they work for your audience. Highlight why these low temp hot peel transfers are superior – think less damage to garments due to lower heat requirements resulting in high-quality finishes on products including complex poly blends. Help inform your customers, that way they know you are offering a new process that works better than ever on that hard to print material.

This move towards incorporating Low Temp Hot Peel DTF Transfers into your business isn’t just about keeping pace with industry trends—it’s about setting yourself apart as an innovator who delivers quality results every time. Ready to take that leap?

Jump into Low Temp Hot Peel DTF Transfers to boost your print shop game. Get the right gear, train your team, and promote hard. It’s not just a trend; it’s your ticket to high-quality prints and happy customers.

Innovations in Fabric Printing Technology

Let’s face it, the fabric printing game has changed. And boy, hasn’t it evolved for the better? Gone are the days when options were limited and quality was often hit or miss. Nowadays, we’re smack in the middle of an innovation wave that’s completely transforming the landscape of fabric printing.

Understanding Low Temp Hot Peel DTF Transfers

The star of this show? Low Temperature Hot Peel DTF transfers. Yes, that mouthful means something pretty cool – a groundbreaking method that’s turning heads left and right.

This innovation isn’t merely a step up; it vaults over conventional approaches such as dye sublimation, marking a significant leap forward. Why? Because it offers unparalleled flexibility without compromising on quality or durability. Whether you’re working with polyester tees or delicate silks, these transfers have got your back.

The Technical Advantages of Low Temp Hot Peel Transfers

- Eliminating Dye Migration: Ever had colours bleed out or spread where they shouldn’t? Harnessing this innovation, we bid farewell to the chaos of bleeding hues, ensuring each color remains precisely where it’s meant to be.

- Diverse Fabric Compatibility: From cotton to polyester and beyond – if you can name it, there’s a good chance these transfers work wonders on it.

- Eco-Friendly Process: We’re talking about reduced energy consumption and fewer chemicals needed than traditional methods require. Optimal for your designs and even better for Earth’s wellbeing.

Revolutionise your prints with Low Temp Hot Peel DTF transfers – the game-changer in fabric printing offering unmatched flexibility, quality, and eco-friendliness. Dive into a world where colour migration is history, and every fabric type is welcome.

Conclusion

So, there we have it. With the arrival of Low Temperature Hot Peel DTF transfers in Australia, screen printers and enthusiasts have entered a revolutionary phase where polyester printing is completely transformed. Gone are the days when your creative zeal was bogged down by material limitations or color fidelity concerns.

We’re not merely witnessing a passing fad within the fabric realm; rather, we’re standing at the threshold of an immense transformation that underscores improvements in speed, adaptability, and excellence. From exploring how DTF trumps traditional dye sublimation to understanding the nitty-gritty of Low Temperature Hot Peel Transfers – we’ve covered ground that marks significant advancements in fabric printing technology.

The bottom line? Whether you’re running a small print shop looking to punch above your weight or simply diving into garment customisation as a hobbyist, embracing DTF transfers is akin to unlocking an arsenal brimming with potential. By leveraging this technique, we’re not only finding answers but completely transforming what we believe is achievable.

We didn’t merely scratch the surface today; we dived headfirst into what makes DTF not just different but decidedly superior. It’s about making sure every piece of apparel tells a story as vibrant and durable as the technology used to create it.

Remember: In an age where personalisation reigns supreme and production speed can make or break your venture, opting for anything less than revolutionary would be selling yourself short. So why settle? Embrace change with open arms because in this case – innovation doesn’t knock twice.