All Posts

Navigating DTF (Direct to Film) Printing Trends in 2024

Navigating DTF (Direct to Film) Printing Trends in 2024

Ever been mesmerised by the dazzling array of hues that cascade through a kaleidoscope? That’s the kind of colour explosion is what we’re seeing with What to Expect in the world of DTF(direct to film) in 2024. Imagine those hues on fabrics, and you’ve caught just a glimpse of what’s brewing.

Eco-consciousness isn’t just a buzzword here; it’s becoming our new standard. Think less waste, more savings – music to any entrepreneur’s ears. And with tech upgrades knocking on our doorsteps, expect safer workplaces humming efficiently underneath.

There air is an electric feeling of anticipation around DTF Transfers Australia, can you feel it tingling across your skin? The future promises more than shiny gadgets and advancements in tech. It’s brimming with the potential for new experiences, and deeper understanding of all things DTF. So let’s have a look at what we think will happen and What to Expect in the world of DTF(direct to film) in 2024.

Table Of Contents:

- Navigating DTF (Direct to Film) Printing Trends in 2024

- Technological Advancements in DTF Printing Equipment

- Hardware Advancements in 2024

- 2024, The Rise of the Home T Shirt Business

- Updating Our Sample Packs

- New Equipment on the Horizon

- FAQs in Relation to What to Expect in the World of DTF(Direct to Film) in 2024

- In Conclusion

Technological Advancements in DTF Printing Equipment

In the ever-evolving world of Direct to Film (DTF) printing, 2023 brought us significant improvements and breakthroughs. From higher quality films to advanced adhesives and ground-breaking ink innovations, the landscape has shifted dramatically.

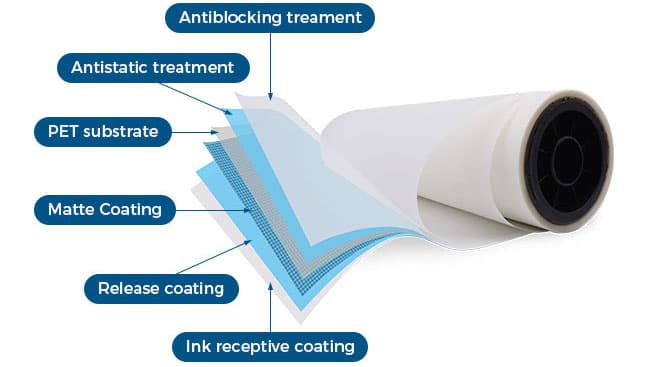

The Evolution of DTF Film Quality

Last year saw a major leap forward in the quality of the DTF film available. Hot Peel Film leveled up its game by matching Cold Peel Film’s performance standards. Not only that, but we also witnessed the introduction of Hybrid Films which can be hot or cold peeled – offering flexibility like never before.

In 2024 We think that the range of speciality finishes will be expanded, giving our customers the ability to be even more creative.

Improved Adhesive Technology

Apart from advancements in films, adhesive technology too took an upward turn with Black Adhesive making remarkable strides. The enhanced version offers better adhesion properties, thereby ensuring superior print results on your T-shirt transfers.

Innovations In Ink Composition

Another milestone achieved was with respect to ink composition – particularly white ink. For years Titanium Oxide had been a staple component of white inks, that is until last year when we welcomed Titanium Oxide Free White Inks into our fold. This development has opened doors for more vibrant prints without compromising on durability or washability.

We anticipate even greater technological leaps coming our way this 2024 as research continues at full pace across all areas within the industry. At DTF Transfers Australia,, we are committed to staying ahead of these trends so you don’t have to! We work closely with wholesalers testing new products as they become available. This ensures we can offer you the best that’s out there in the world of DTF Custom Transfers.

Keep your eyes peeled for what’s coming next and remember to get in touch if you have any queries or need advice on how these advancements could benefit your business or hobby.

Hardware Advancements in 2024

The future of DTF (Direct to Film) is looking bright and promising, with technological advancements predicted to revolutionise the industry in 2024. This evolution will be driven by major brands such as Brother, Roland, and Mimaki. These pioneers have already developed their first-generation printers for DTF transfers, paving the way for more sophisticated hardware. And removing the reliance on Chinese made printers and hardware.

More Major Brands Entering the Market

In addition to Brother, Roland, and Mimaki who are already making waves in this space, we anticipate other big names joining the fray. The entry of these new players would mean a wider variety of high-quality printers designed specifically for DTF applications – from compact models perfect for small print shops or hobbyists at home to industrial-grade machines capable of handling large-scale production runs.

New Printers Designed Specifically For DTF Transfers

We expect that printer technology will evolve significantly over the next few years with features tailored specifically towards improving efficiency and quality in producing custom printed T-shirt transfers using direct-to-film methods. Expect faster printing speeds without compromising on detail accuracy or colour fidelity; automatic maintenance functions that reduce downtime; improved ink systems offering broader colour gamuts while minimising waste; plus advanced software integration capabilities enabling seamless workflow management.

Dryers And Shakers: Essential Complements To Printing Hardware

Beyond just printers though, there’s also likely going to be progress made on associated equipment like dryers and shakers which play crucial roles within any successful DTF operation. Better performing dryers can speed up the curing process and enhance print durability, while more efficient shakers can ensure even powder distribution for consistent results.

The year 2024 is shaping up to be an exciting time in the world of DTF. With these hardware advancements on the horizon, screen printers and small print shops will have a wider range of options at their disposal to cater to different customer needs. Hobbyists looking for T-shirt transfers will also benefit from improved quality and versatility that these new technologies bring.

The Dream of Liquid Adhesive Moves Closer

As we look ahead to 2024, the DTF (direct-to-film) industry is on the cusp of a significant breakthrough. The long-held dream of removing powder adhesive and replacing it with a printable version is edging closer to reality. This shift promises not only to streamline production processes but also enhance the quality and durability of T-shirt transfers.

SubliStar, one of the leading names in DTF printing technology, has announced its commitment towards making this innovative approach available by year-end. They are investing heavily into research and development, promising a new era for print shops who use DTF Transfers.

Moving Towards Printable Adhesives: Why is it a Game-Changer

This leap forward in DTF technology will revolutionise how custom printed T-shirt transfers are made. By eliminating powder adhesives from the process altogether and introducing liquid or printable adhesives instead; precision can be increased significantly while reducing waste.

- Better Precision: With printable adhesive application being applied prior to curing means that every detail would be captured more accurately than ever before.

- Reduced Waste: It’s no secret that using powdered adhesives often results in excess being wasted during application. However, when you’re dealing with liquid adhesive that can be applied precisely where needed – wastage becomes virtually non-existent.

- Unknown Maintenance: While the required maintance is not known, the hope is that it will be greatly reduced, and become more automated and user friendly.

A New Era for DTF Transfers Australia

We at “DTF Transfers Australia“, enthusiastically anticipate this advancement as it aligns perfectly with our mission – providing top-quality custom printed T-shirt transfers. This technological leap will enable us to offer our customers even better products, with superior detail and durability.

As we move closer towards the end of 2024, we eagerly await SubliStar’s unveiling of this technology. With them leading the charge, it is only a matter of time before other companies follow suit in adopting printable adhesive technology.

2024, The Rise of the Home T Shirt Business

In 2024, we predict a significant rise in individuals launching their own t-shirt brands using custom DTF (Direct to Film) transfers for decoration. This surge is not just due to the flexibility and convenience that DTF offers but also because it’s an excellent side hustle opportunity.

The Importance of Skills in DTF Printing

While starting your own t-shirt business with DTF Transfers Australia might seem straightforward, there are essential skills you need to master. It’s more than simply downloading an image and slapping it onto a shirt; design proficiency plays a crucial role too.

Canva and AI Image generation tools can be great assets for beginners or those without much graphic design experience. However, these tools should only serve as stepping stones towards developing your unique style and brand identity.

Necessity of Original Content Creation & Editing Skills

To truly thrive in this industry by 2024, having original content creation skills will be paramount. Customisation is at the heart of every successful t-shirt business; hence being able to create or edit images tailored specifically for your target audience will set you apart from competitors.

- Create: Learn how to use software like Adobe Illustrator and Photoshop proficiently so you can develop original designs that resonate with your customers’ tastes and preferences.

- Edit: Not all downloaded images fit perfectly into different apparel sizes or colours. Therefore mastering editing techniques ensures each piece looks professional regardless of its size or colour scheme.

Remember: success lies not just in selling products but creating a brand that your customers identify with. By honing these skills, you can ensure your t-shirt business is not just profitable but also sustainable in the long run.

The Rise of AI Art for T-Shirt Designs

As we move further into the digital age, technology continues to revolutionise every aspect of our lives. The realm of custom printed t-shirt transfers is no exception. A significant trend that’s set to shape the future in 2024 is the rise of Artificial Intelligence (AI) art for t-shirt designs.

In recent years, advanced image generation tools such as Dalle.3, Midjourney, and Leonardo have been developed with cutting-edge features that are transforming how screen printers, small print shops and even customers create their designs.

How AI Art Creation Works?

These innovative platforms use machine learning algorithms to generate unique images based on input parameters defined by users. For instance, you could input a prompt like ‘an abstract representation of summer’ or ‘a stylised cat wearing sunglasses’, and it would produce corresponding artwork within seconds.

The Impact on Printing Businesses

This technological advancement holds great potential for businesses specialising in custom DTF Transfers. It significantly reduces design time while offering endless possibilities for creativity. This means more diverse product offerings without needing an extensive team of graphic designers or spending hours brainstorming ideas manually.

A New Wave Of Creativity For Hobbyists

Hobbyists looking for unique t-shirt transfers will also greatly benefit from this trend; they can now effortlessly create personalized pieces using these AI-based tools without any professional design skills required.

It’s not only about creating new designs but also about reinventing existing ones with a fresh perspective which was never possible before at such scale & speed!

Finding Your Unique Style With AI Tools

- Explore: Try different AI tools to see which one suits your style and needs best.

- Create: Experiment with various inputs to generate unique designs. Remember, the more specific you are, the better results you will get.

- Innovate: Don’t be afraid to push boundaries and think outside of the box. The beauty of these tools is that they allow for unlimited creativity!

The rise of AI art in t-shirt design promises an exciting future filled with endless possibilities for both businesses and hobbyists alike. As we look forward to 2024, it’s clear that this trend will significantly shape how custom printed t-shirt transfers are designed and produced.

The t-shirt business is poised to grow in 2024, with a surge in home-based entrepreneurs using DTF transfers, fueled by its flexibility and profit potential.

Key skills in DTF printing and design are crucial, with AI art platforms like Dalle.3 and Midjourney simplifying design creation.

This trend is revolutionising the industry, enabling both businesses and hobbyists to effortlessly produce unique, custom designs, marking a significant shift towards more innovative and personalised t-shirt printing.

Updating Our Sample Packs

We’ve been listening to your feedback and we’re excited to announce some changes coming in 2024. Here at DTF Transfers Australia, we are committed to providing the best possible service for our customers, which includes continually improving our products based on your suggestions.

New Labeling System

In response to customer requests, we will be introducing a new labeling system on our transfers provided in the sample pack. You’ll now find clear markings indicating whether they are hot peel, cold peel or hybrid film. This change is designed to make it easier for you – whether you’re a professional screen printer or hobbyist – this will help to identify the type of transfer quickly and accurately.

Reduced Packaging Waste

We understand that sustainability matters greatly in today’s world. That’s why instead of offering three separate packets inside the sample packs as before, we have decided to consolidate them into one single pack. By doing so, not only do we simplify things for you but also significantly reduce packaging waste.

This move aligns with our ongoing commitment towards environmental responsibility while ensuring that you still get access to all the variety and quality expected from DTF Transfers Australia.

Your Feedback Matters!

The decision behind these updates was driven by valuable feedback received from you our customers back in December 2023. We believe that open communication leads us closer towards perfection every day! So please continue sharing your thoughts about what works well and where improvements can be made via email.

We hope these changes will enhance your experience with our DTF printing even further! Stay tuned for more exciting announcements and improvements throughout 2024!

New Equipment on the Horizon

As we strive to bring you one of the best quality services in the DTF transfer industry, we’re thrilled to announce that we’ve invested in a state-of-the-art printer. This investment is part of our ongoing commitment at DTF Transfers Australia to enhance efficiency and deliver you the best transfers available.

The Power of Advanced Print Software and Technology

This new machine isn’t just any regular printer; it utilises cutting-edge print software and technology designed for superior performance. The advanced capabilities of this equipment mean not only faster turnaround times but also precision printing for flawless results every time.

Titanium Oxide Free Inks: A Game Changer

We are equally excited about using Titanium Oxide Free inks sourced from Japan. These revolutionary inks have been available for some time, albeit difficult to procure until now. However, come 2024, these high-quality inks will be more readily accessible – an advancement that promises improved quality prints and simplified maintenance processes on our end.

- Better Quality Prints: With Titanium Oxide Free ink, expect richer colours and sharper images on your custom printed T-shirt transfers – taking visual appeal up a notch!

- Simplified Maintenance: This type of ink doesn’t clog print heads as easily as traditional ones do which means less cleaning and maintenance work – saving both time and resources!

We are introducing a new labeling system for easier identification of transfer types in our sample packs, reducing waste by consolidating sample packs packaging, and responding to customer feedback for continuous improvement.

Additionally, the company is investing in advanced printing technology with state-of-the-art equipment and Titanium Oxide Free inks, promising faster turnaround, better print quality, and simplified maintenance. These changes reflect their dedication to leading in quality and efficiency in the DTF transfer industry.

FAQs in Relation to What to Expect in the World of DTF(Direct to Film) in 2024

Is DTF printing profitable?

Yes, with a good market strategy and quality output, DTF can help you make a profit with your T Shirt and Apparel Printing Business.

What is the disadvantage of DTF printer?

The initial setup costs can be steep, and there’s a step learning curve to nailing the process down and produce quality transfers.

How long does direct to film printing last?

DTF prints hold up well – expect them to stick around through plenty of washes if done right.

What is the best printer to convert to DTF?

We strongly recomend against conveting a printer to become a DTF Printer, there are now pleanty of options available for purchase.

In Conclusion

Expect vibrant colours and eco-savvy trends when you dive into what to expect in the world of DTF in 2024. This year is all about slashing waste, saving cash, and keeping it green.

Remember those tech upgrades? They’re setting up shop to make workplaces safer and more efficient than ever before.

And software? It’s now calling the shots for faster turnarounds that keep your printing on beat without missing a note. Think small but mighty printers delivering quality that punches above their weight class – that’s innovation at work.

In essence, get ready for a wave of fresh opportunities with DTF technology this year. Ink advancements are here too; they’ll give life to prints like never before.

Epson printheads? They’re the quiet heroes behind sharper details across every inch of fabric. The bottom line: stay tuned as direct-to-film keeps redefining our colourful world one print at a time.